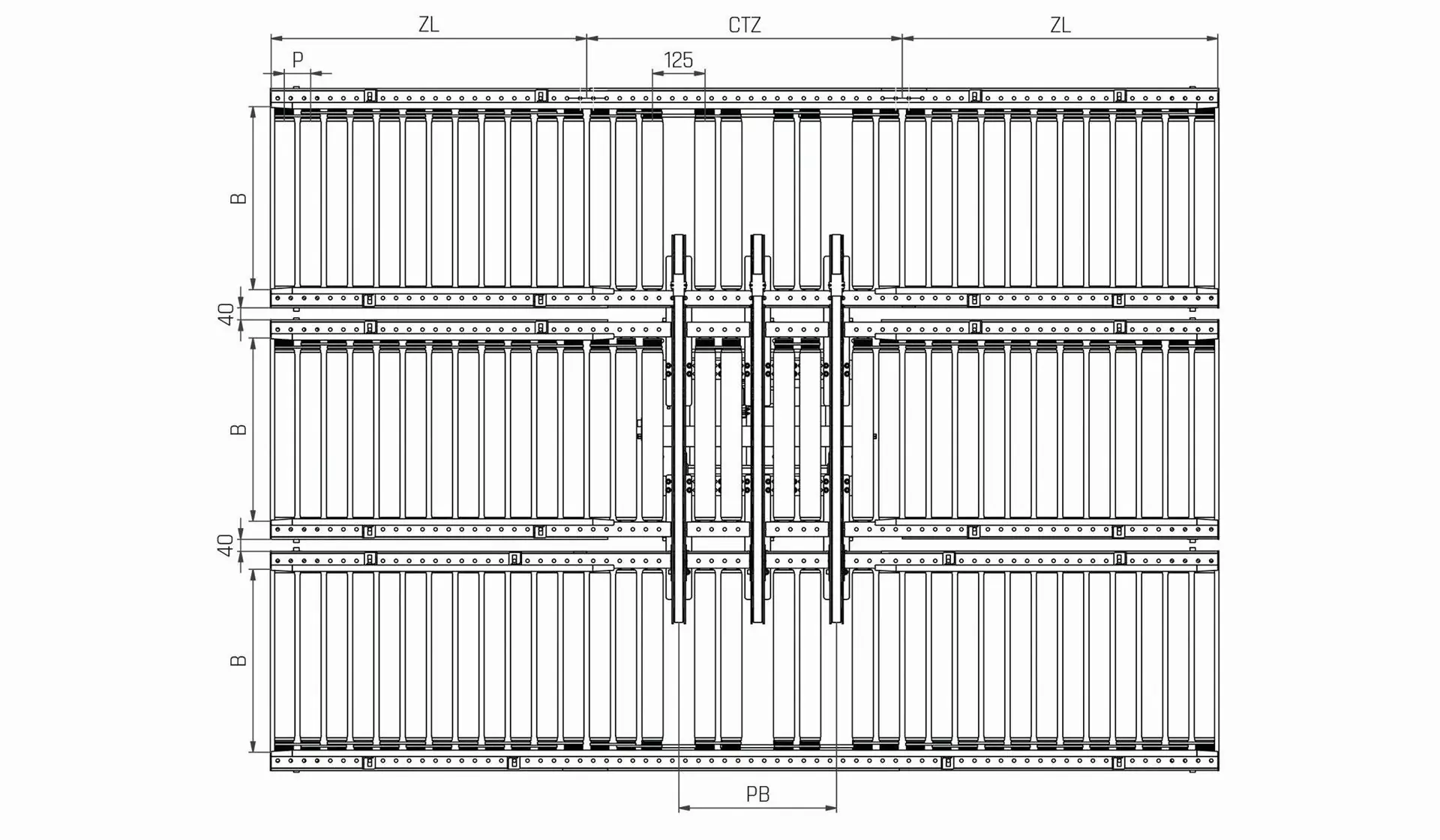

Node where the load is redirected from the main line to the parallel track. To move, objects are lifted on skids by means of an electric motor, and then transported using transmission belts to an adjacent line. In order for the load to be transferred correctly, the device uses properly extended skids that fit into the frame of the adjacent conveyor. Parallel tracks are made of zone conveyors, in which the drive activates the rollers when the object has been placed completely on the surface of the conveyor.