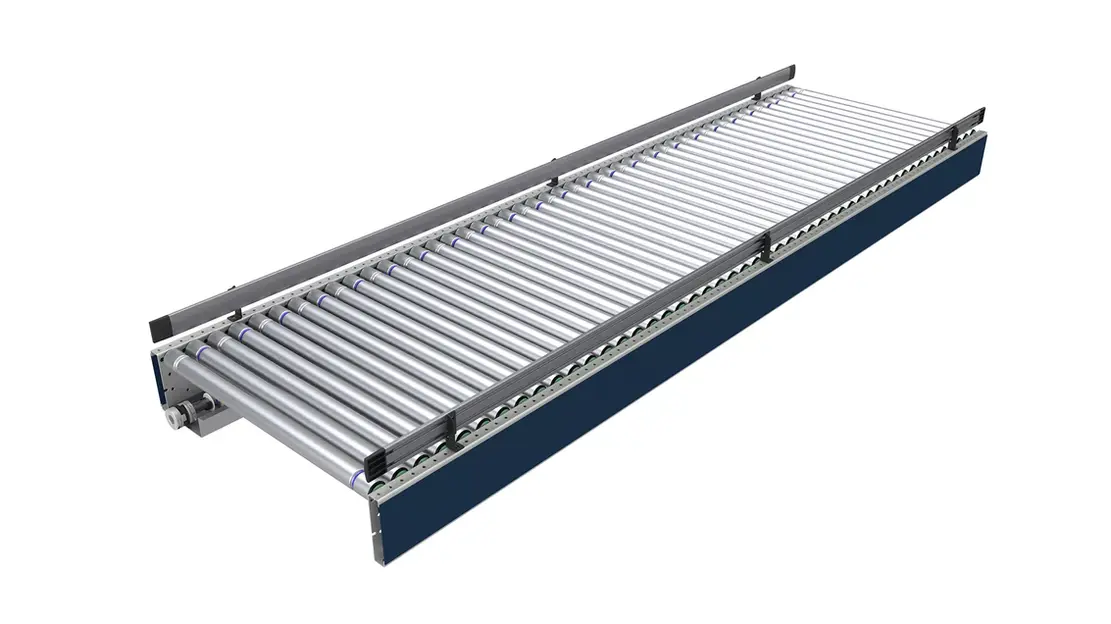

24V Conveyors

24V conveyors are driven by electric rollers connected by multi-groove belts to the other rollers. The design of this type of device allows for configuration with other systems such as gravity conveyors, belt conveyors, transfers, switches and pop-up modules. Together with an extensive sensor system, they create a fully automated internal transport system. The main task of 24V conveyors is the accumulation of loads via separate buffer zones. Each zone is powered by a separate electric roller with the possibility of changing the speed or its direction.

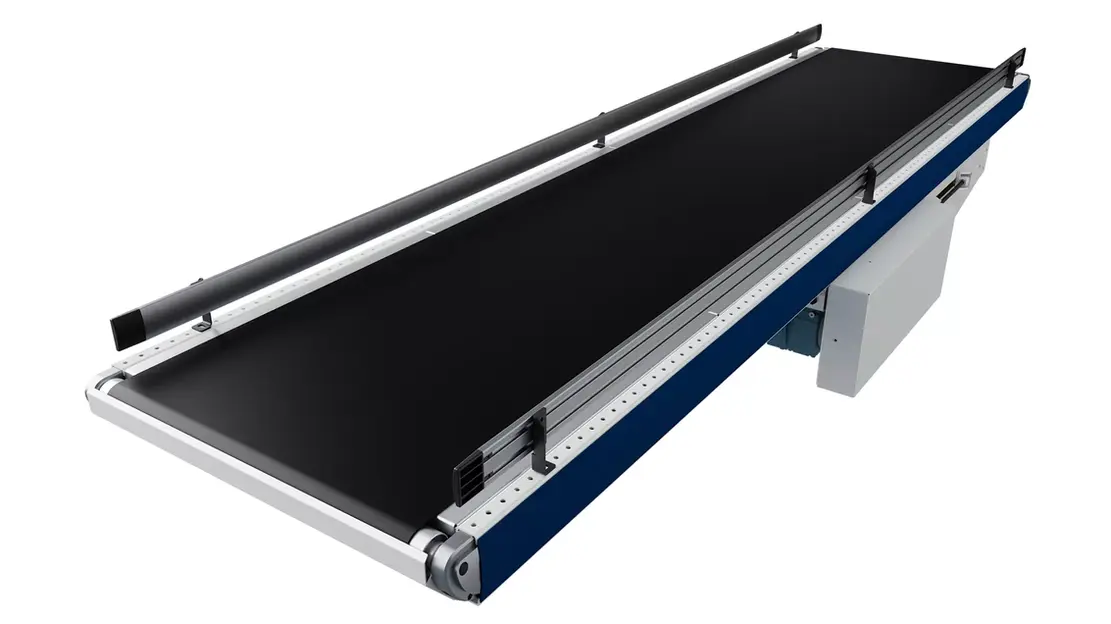

Leveling conveyor

The leveling conveyor positions the item to the selected side of the band profile. It is used when precision is required when changing the direction of movement of the transported load. It is recommended to place the leveling conveyor before the node equipped with specialist devices...

30° driven arc

The driven arc changes the direction of the load movement. The conical shape of the rollers allows the goods to be held between the side profiles. The use of a controller allows for pressure-free buffering. The device consists of a steel frame bent at an angle of 30°, an electric roller, five rollers...

45° driven arc

The driven arc changes the direction of the load movement. The conical shape of the rollers allows the goods to be held between the side profiles. The use of a controller allows for pressure-free buffering. The device consists of a steel frame bent at an angle of 45°, an electric roller, eight conical rollers...

60° driven arc

The driven arc influences the change of the direction of the load movement. The conical shape of the rollers allows the goods to be kept between the side profiles. The use of the controller allows for pressure-free buffering. The device consists of a steel frame bent at an angle of 60°, an electric roller, eleven rollers...

90° driven arc

The driven arc influences the change of the direction of the load movement. The conical shape of the rollers allows the goods to be kept between the side profiles. The use of the controller allows for pressure-free buffering. The device consists of a steel frame bent at an angle of 90°, two electric rollers, sixteen...

30° driven angle connector

The angle connector, depending on its location, helps to introduce loads onto the main line or lead them out onto a side line. When introducing them onto the main line, it uses breaks in the flow of materials. It works directly with a switch or pop-up. The device consists of a steel frame...

.webp)

45° driven angle connector

The angle connector, depending on its location, helps to introduce loads onto the main line or lead them out onto a side line. When introducing them onto the main line, it uses breaks in the flow of materials. It works directly with a switch or pop-up. The device consists of a steel frame...

Zone gate

The powered transition gate allows free passage through the main conveyor line. Lifting the gate stops the transported loads until it is lowered. It consists of a steel conveyor frame, electric rollers, PolyVee rollers, controllers, sensors, a system... See also our Gravity Conveyors .